About Us

Athletic Field Services, Inc. has been designing and building running tracks in the Midwest since 1982. We handle all aspects of track design, construction, resilient surfacing, and lines. Specializing in the high school and small college market, we focus on the needs of our customer and also maintain high standards of service. We make sure that everything is right from excavation and drainage to paving, surfacing, lines and landscaping. AFS actively supports high school track coaches associations in Wisconsin, Illinois and Minnesota. We enjoy meeting the coaches and athletic directors. We are proud to be able to promote the sport of track and field.

What we do

AFS began as a licensed Seal-Flex® surfacing installer. Seal-Flex® is a latex bound rubberized resilient surface that has a proven record with hundreds of successful installations nationwide with over 275 installations here in the Midwest. Several years ago, we also began offering our customers the option of polyurethane track surfaces to compliment our already successful Seal-Flex® line up. We have our own professional line painting division so we can customize your facility and guarantee accuracy at either the high school or college level.

We are licensed, bonded and fully insured. Our company is a member in good standing of The American Sports Builders Association.

Seal Flex

Polyurethane (Beynon)

LATEX TRACKS (SEAL-FLEX®) Beauty . . . Quality . . . Seamless . . . Peace of Mind! SEAL-FLEX® has been rigorously tested under ASTM standards for tensile strength, spike pick-up, freeze / thaw resistance, abrasion, light exposure and chalking. It has been proven to be tough, durable and virtually maintenance free.

Polyurethane (Beynon)

Polyurethane (Beynon)

One of the most important considerations when selecting a track and field system is the examination of lifecycle cost and when comparing rolled rubber sheet goods to polyurethane surfaces, the increased initial cost of the sheet good is clear. However, when the time comes for track refurbishment, the gap widens even more. Unlike a polyurethane system, a rubber sheet good cannot be resurfaced, but rather, requires total replacement after 12 to 15 years. With this comes the cost of milling and repaving the asphalt base as the existing subsurface is damaged during track removal. A Beynon polyurethane track is more cost effective and virtually maintenance free.

Line Painting

Line Painting

Athletic Field Services, Inc. is certified and uses top of the line machinery and expertly trained staff to line athletic tracks.

Line Painting

Seal-Flex® Tracks

Features and Benefits of Seal-Flex®

You want a track that is a source of pride and an asset to your school. A SEAL-FLEX® track, in plain words, lets you have a better track for less money. You get all of the advantages of an all-weather synthetic surface at an affordable price and you continue saving because of fewer maintenance requirements and lower maintenance costs.

A latex bound SEAL-FLEX® track offers you the resilience that athletes and coaches love, combined with the safety and traction of an all weather surface. A SEAL-FLEX® track keeps its good looks for years with very little maintenance and is always an attractive addition to the athletic site. SEAL-FLEX® is installed by a network of experts who understand the process and the materials. We have installed hundreds of tracks and we would love to send you a list of their owners with names and telephone numbers.

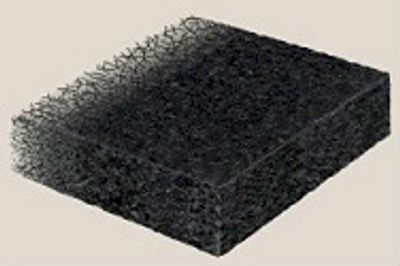

Seal-Flex® Difference

What makes SEAL-FLEX® better than other comparably priced surfaces is its unique construction and application process. Traditional granular rubber surfaces incorporate randomly dispersed rubber "pebbles" that "float" in a binder. As the binder begins to deteriorate with age and climatic changes, these "pebbles" are free to separate and break away from the surface. The SEAL-FLEX® matrix is composed of interlocking stranded rubber particles bound by a tough latex compound and permanently bonded to an asphalt substrate. The chemical interaction of these materials combined with the interlocking rubber strands creates a durable seamless, web-like mat surface. Unlike granular surfaces, SEAL-FLEX® rubber particles won't "pick" out or break loose under the regular punishment of track shoe spike action. Its chemical composition resists oxidizing or degeneration under ultra-violet rays or climatic changes. The surface remains resilient season after season, even in cold weather. Due to its unique composition, SEAL-FLEX® reduces the risk of running-related injuries common with harder surfaces. Choose the surface that's right for you. SEAL-FLEX® is available in various colors and thickness, depending upon your requirements. Ask your SEAL-FLEX surfacing specialist for all the details to "get on the right track".

Types of Seal-Flex® tracks

LR-4: Four coats, minimum depth of 1/4"

LR-6: Six coats, minimum depth of 3/8"

LR-8: Eight coats, minimum depth of 1/2"

CRS-5: Three coats black, two coats color, minimum depth of 5/16"

CRS-6: Four coats black, two coats color, minimum depth of 3/8"

CRS-8: Five coats black, three coats color, minimum depth of 1/2"

GR-5: Five coats granular rubber, minimum depth of 3/8

GR-7: Seven coats granular rubber, minimum depth of 1/2"

FAQs

Q: I have an LR-5/LR-6 surface, what length spikes are recommended?

A: A maximum of 1/4"

Q: Can I rollerblade on the track?

A: NO, bicycles, rollerblades, motorcycles and strollers are not recommended, it can void your warranty. Limit vehicular traffic to mowing and maintenance equipment.

Q: How do I remove mud and other debris from my track?

A: Mud can be removed with a water nozzle and/or an air broom blower. Brooming can be quite difficult. In order to remove loose debris like grass clippings we recommend a Billy Goat 8hp power blower.

Q: My track was vandalized, can I fix it myself?

A: We can send one of our specialist to come take a look at the damage and do the repair. Most repairs are inexpensive and we prefer not to send patch kits.

Q: My track is starting to show some wear, do I need a new track?

A: We recommend resurfacing every 7-10 years to keep your track in tip top shape. Our specialists can evaluate your track to give you the best choice on what needs to be done.

Polyurethane

Beynon: BSS-50

The BSS-50 combines SBR or EPDM granules with our polyurethane binder to created track surfaces for a great value. Porous, Cost-effective and an ideal entry-level polyurethane track.

Beynon: BSS-100

Porous, Paved-In-Place Base mat, Structural Spray Track System. Resilient, durable and IAAF Certified, the BSS-100 is the quality track surface solution for schools and local communities who are in search of an all-weather track system. Boasts multi-use capabilities and a proven longevity. Delivers consistent energy return throughout its life cycle. The BSS-100 is supported by a comprehensive warranty. Water permeable and requires virtually no maintenance.

Line Painting Specifications

Lines and event markings are painted according to the National Federation of State High Schools rule book and in coordination with the athletic staff.

Painting takes about two working days, and the temperature must be above 40 degrees with dry conditions. All event markings are clearly identified in lane two with 3” high letters. Common finish line is 4” wide. The line paint material is a water base acrylic latex, compatible with the rubber surface. Includes choice of line colors, (white is highly recommended), large shaded numerals that can be matched to your school colors, race identifications, and shaded team name in your school colors. AFS provides accurate and quality lining work.

Contact Us

AFS Team

Devin Wheat- President/ Sales-Marketing

Dan Devoy- Project Manager

Kirk Chally- Foreman/Polyurethane

Kelly Wheat- Business Manager

Hours

Mon | 08:00 am – 04:30 pm | |

Tue | 08:00 am – 04:30 pm | |

Wed | 08:00 am – 04:30 pm | |

Thu | 08:00 am – 04:30 pm | |

Fri | 08:00 am – 03:30 pm | |

Sat | Closed | |

Sun | Closed |

Photo Gallery